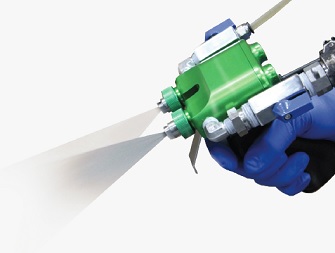

HIGH PRODUCTION INSTANT-SET SPRAY SYSTEM

Pneumatic trigger, custom aluminum body, and proprietary spray tips engineered specifically for Triton’s proprietary, instant-set liquid rubber and acrylic technologies. Our spray gun has a lightweight, durable handle with separate valve controls and quick-link disconnects. The gun was designed in-house and is 100% American-made, with even the smallest parts machined at Triton’s Iowa factory.

Cart & Hose Assembly

Pumps & Cleaning

The main coating/product pump is an industrial, electric-powered diaphragm pump with 580 psi max output pressure. The pump is easily cleaned with soap or Triton’s Pump Cleaner and water. It is conveniently located on top of the cart and does not need removed for cleaning. The catalyst pump is a 100-psi air-driven diaphragm pump and is flushed with only water. The spray rig includes an on-board air compressor to run the catalyst pump and actuate the spray gun.